With the “Big One” a big possibility and the ongoing industrial developments in the country, the government should revisit the Philippine steel production policy. The Big One is the predicted 7.2-magnitude earthquake that may hit Metro Manila and neighboring areas.

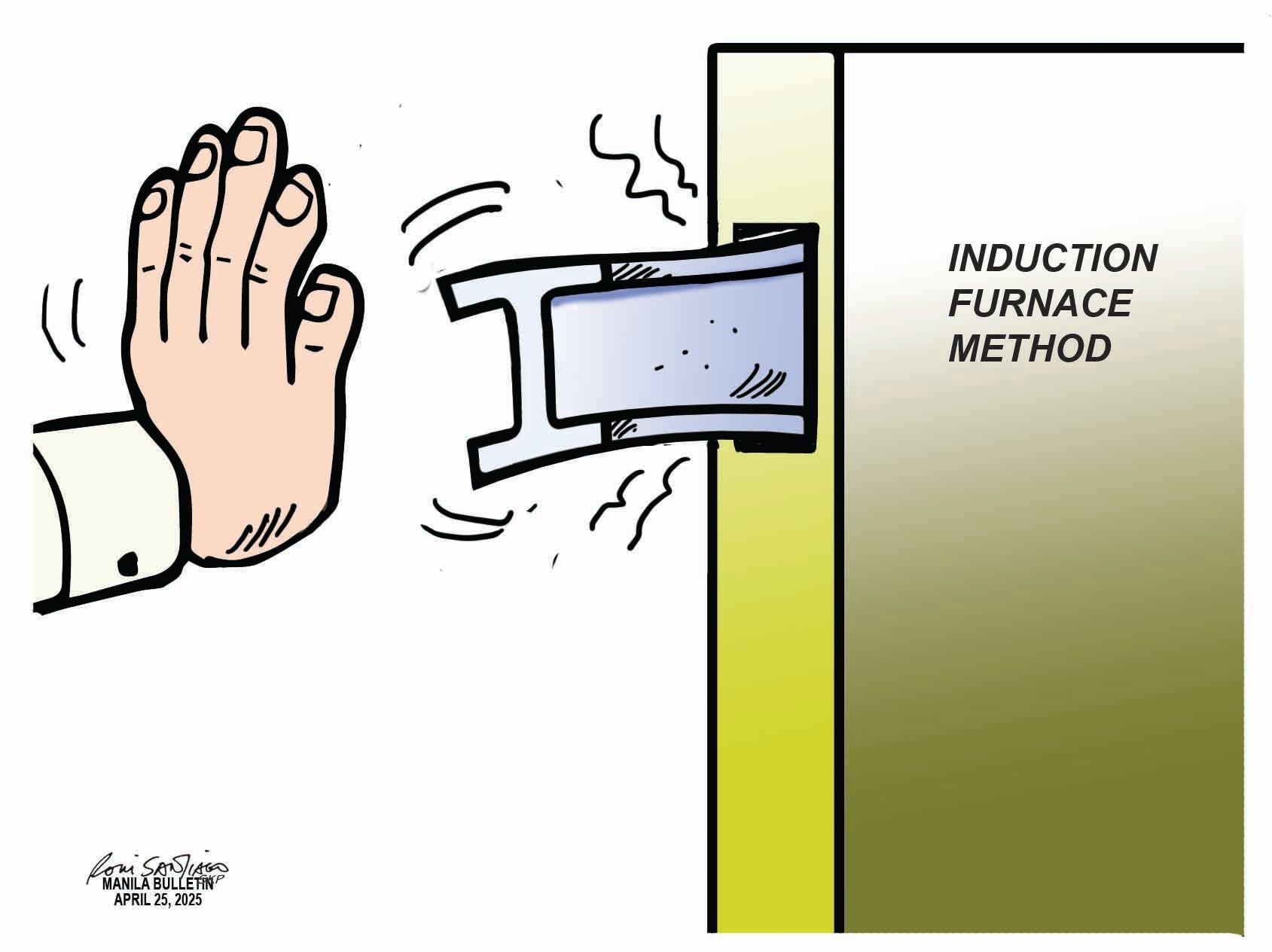

While the country seeks to bolster its steel production to meet infrastructure demands, the method by which this steel is produced warrants urgent scrutiny, especially with the feared Big One. However, the widespread use of induction furnaces (IFs) in steel manufacturing poses significant environmental, health, and economic risks. With these developments, it’s crucial for the Philippines to follow the lead of other nations by imposing a ban on this outdated and hazardous technology.

Induction furnaces, particularly those refurbished and imported from China, are known to have adverse safety and environmental issues. In fact, China already banned the use of the induction furnace method.

Induction furnace-produced steel often fails to meet safety standards. The Philippine Iron and Steel Institute (PISI) has highlighted that steel products from IFs are substandard, with poor mechanical properties such as low elongation and strength. This compromises the structural integrity of buildings and infrastructure, especially in a country prone to natural disasters like earthquakes and typhoons.

Beyond quality concerns, these furnaces lack advanced pollution control systems, leading to the emission of harmful gases and particulate matter. In Sta. Maria, Bulacan, residents have reported foul odors, dirty air, and noise pollution emanating from steel plants utilizing IFs. Such pollution not only degrades air quality but also poses serious health risks, including respiratory illnesses and cardiovascular diseases.

The global community has recognized the dangers associated with IFs. It was in 2017 when China phased out induction furnaces due to their high pollution levels and inconsistent product quality. Similarly, a group of ASEAN steelmakers have called for a ban on IFs, citing their obsolete technology and environmental hazards. These international actions underscore the necessity of eliminating the use of the induction furnace method in steel production to safeguard public health and ensure the production of high-quality steel.

Some of the country’s local governments are beginning to take action. For instance, Sta. Maria, Bulacan, has enacted Ordinance No. 704, prohibiting the use of IFs and mandating the modernization of steel plants to eco-friendly technologies. This initiative aligns with the effort of the Department of Environment and Natural Resources (DENR) to tighten environmental standards in steelmaking.

However, these local measures must be complemented by national policies, particularly on quality standards for steel production. For instance, the Bureau of Philippine Standards could not act in the absence of a policy or law that bans induction furnaces. So, there is a compelling reason for the government to come up with a policy banning the use of induction furnaces nationwide. But any new policy must be coupled with incentives for steel manufacturers that adopt cleaner and more efficient technologies. This approach would not only improve product quality and ensure the protection of the environment and public health. It must also enhance the competitiveness of the Philippine steel industry in the global market.

The continued use of induction furnaces in steel production is an antiquated method that the Philippines can ill afford to maintain. The substandard steel quality, environmental degradation, and health risks associated with IFs demand decisive action. By banning induction furnaces and embracing modern, sustainable steelmaking technologies, the Philippines can pave the way for a safer, healthier, and more prosperous future.

Let’s keep in mind that the Philippines is vulnerable to earthquakes being located within the Pacific Ring of Fire. So, now is the time to retire the induction furnace method. Tomorrow might be too late.