The story of the guava jelly you likely bought from a food store in Bacolod City

Filipinos are familiar with guava jelly, a thick syrupy jelly made from native guavas which grow abundantly in many parts of the country, even in the backyards.

For generations, when the fruit is in season, many families would make them according to their own recipes, a relatively universal one whose outcome is dictated by the timing of shifting from one step to the other. So, it can be too thick, or too thin, too sweet or tart. The product would give a surprise taste.

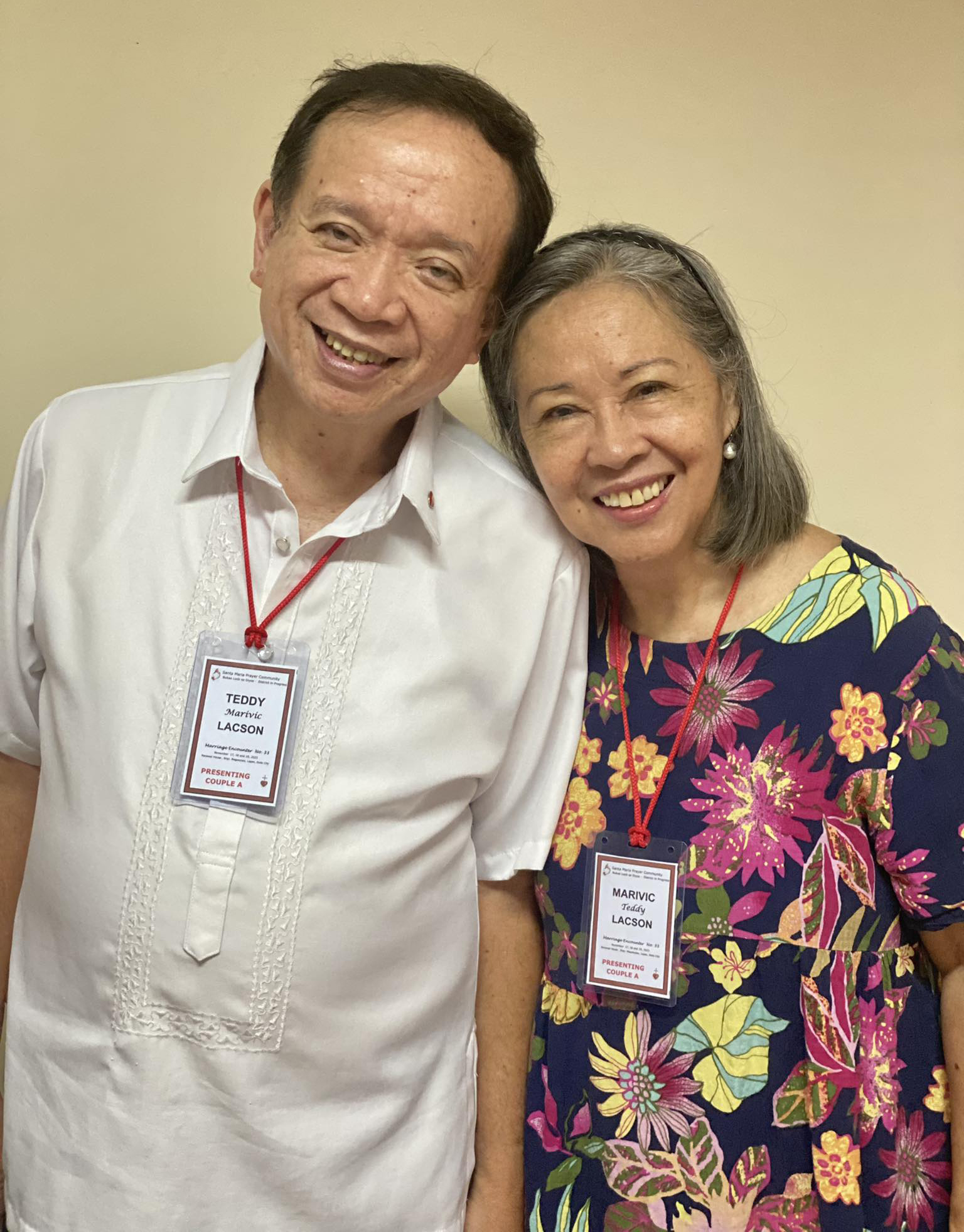

It took a 71-year-old retired electrical engineer, a scion of a prominent family in Negros Occidental, to put scientific order on the process, as a result, producing a guava jelly that today – according to its popularity – has been acclaimed as the one with the “perfect taste and consistency.” Perhaps the engineer had shared the recipe because the same flavor is carried by the jelly in jars sold in the popular pasalubong stores but with different labels. Or maybe this scion is producing it himself as a hobby.

The retiree, Teddy Lacson, who was a musician during his high school days, stumbled upon the recipe as most do – through trial and error.

The trial started in 2015, after he saw a vendor at a public market selling piles of native guavas. He purchased all of the vendor’s guavas, and asked her to bring some more the next Sunday. Word soon got around that Teddy was buying any amount of native guavas, and many vendors contacted him to sell. Teddy had created a network of reliable sources during the fruit season. When not in season, Teddy rested.

The first products which were processed by a cook, were inconsistent – some were good, others, bad. After three years of guessing the outcome of his products, Teddy decided to do the whole production process himself.

“My brother gave me a guava jelly recipe from a 1991 issue of Good Housekeeping magazine, with some tips from a British friend. Of course, the recipe was very American and I had to substitute some ingredients and adjust some procedures. I used the Good Housekeeping recipe as a guide and after so many trials and errors in cooking.”

“Making guava jelly is a bit complicated. The first stage is you slice the guavas and simmer them in water for two hours until they are soft and then strain them in a cloth to remove the seeds and other guava flesh.” For straining, he uses an upside-down stool to hold the cloth, with a large container under it to catch the pure guava juice.

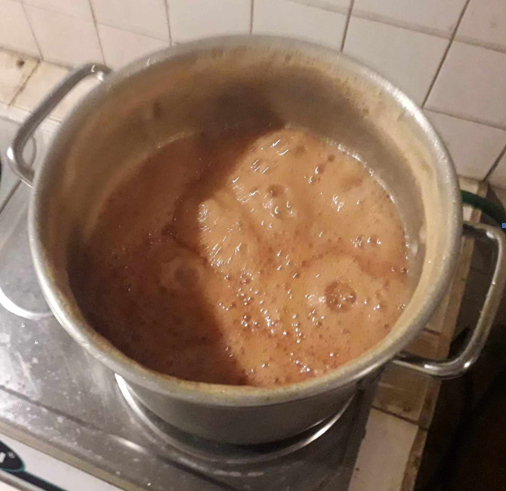

“The second stage is boiling the guava juice, adding sugar and calamansi juice.”

He said the “tricky part” is when one can recognize that the mixture is already cooked. “Total cooking time varies from an hour to an hour and 45 minutes.”

The next few minutes will determine the consistency or the jelly. “You have a window of about two minutes to remove the mixture from the stove and pour it into the sanitized bottles. If you remove them before that, the guava jelly will be like a syrup. If you remove them after the window, the mixture will be too thick.”

After cooking the jelly for years, Teddy said he now just “reads the bubbles” to know the right time to remove the mixture from the fire. “Scientifically, the bubbles’ appearance changes as the mixture thickens,” he said.

The third stage is pouring the mixture into the sanitized bottles, removing the froth, and covering the bottle while it is hot to make sure no bacteria is present,” Teddy explained.

During the pandemic when movement was restricted, he made about 100 cases of guava jelly bottles, all by himself. “I am a one-man guava jelly factory.”

He has even calculated that he needs three kilos of the native fruit to make 24 bottles of the jelly with the perfect consistency.

“The guava jelly production started like a retirement hobby. It provided some income but the problem is the seasonal nature of the fruit which determines the availability of the main ingredient.

“If I will seriously go into this business, I need a long-term plan to either plant guavas in my property, or set up a contract grower,” Teddy said, his engineer’s mind thinking far ahead.

Meanwhile, he’s still a hobbyist slicing guavas, boiling it, straining it with the help of an inverted stool, and “reading the bubbles” to determine the perfect time to get it off the fire.

If you are a friend of his wife, Marivic, or his two married daughters, you’d likely have been gifted a bottle or two of that perfectly consistent guava jelly.

Teddy and his wife live in Bacolod City, while their children have settled abroad. They are surrounded by family members up to fifth-degree cousins, and friends from high school and college. Likely, they all have tasted Teddy’s guava jelly, and perhaps one or two, even have Teddy’s exact recipe.

If you are in Bacolod City, check out the guava jelly in any of the popular souvenir shops. It comes with many brands, though, but it’s likely made the Teddy way. Perhaps by now, someone has figured out how Teddy’s recipe goes.